EDIT: I don't use this spreadsheet anymore. I use the method outlined in the thread here:

topic4911-60.html" onclick="window.open(this.href);return false;

A sample spreadsheet is included in my post in that thread. I'm going to leave this spreadsheet here just in case there's some information available.

A better update to the spreadsheet is here:

viewtopic.php?f=32&t=6313&p=60882WARNING: The MAF and the injectors can not be scaled simultaneously since we rely upon a AF

Ratio to scale them.

MAF: I scale the MAF in stages and try to scale the MAF using AFR data that is steady state. In other words d(MAF)/d(time) is small or zero.

1. Closed loop range between idle and 60 g/s.

2. Open loop low range using WBO2 and 5th gear logs with about 50% to 70% throttle and WGDC = 0.

3. Open loop middle range using WBO2 and 3rd gear WOT logs and WGDC = 0.

4. Open loop high range using WBO2 and 3rd gear WOT logs with normal WGDC and normal boost levels. For this, I change the arbitrary AFR target to 10.5 to be conservative since MAF is unknown.

5. Change AFR table back to real targets and then make fine adjustments to AFR targets to hit correct AFR based upon rpm and load. MAF scale is never perfect.

6. Do all of the above with one type of fuel.

To scale the MAF in closed loop, I use the closed loop corrections. To simplify the job, I use this spreadsheet to tabulate the data for me. Instructions are embedded in the spreadsheet.

As an alternative to this spreadsheet, you can also just adjust the AFR Learning ranges and use AFR Learning to estimate the deltas. The only problem that I have found with this method is that AFR Learning D takes a long time stabilize since most people do not drive steady state at 40-60 g/s. Unless you are logging your driving, there is no way to know when is there enough data.

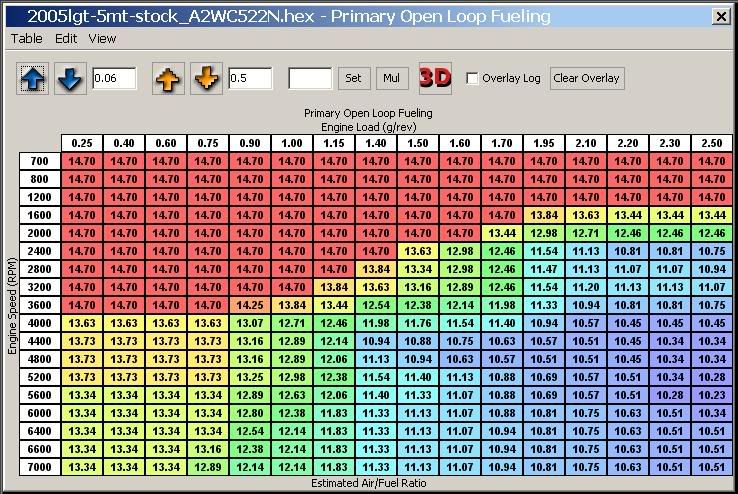

For open loop MAF scaling, it is easier to scale the low-range MAF (60-120 g/s) if the AFR target is lowered in the CL range to something less than 14.7. Here is an example of a simplified AFR target table that can be used to scale the MAF in open loop using a WBO2.

Stock AFR Target:

Simplified AFR Target for scaling MAF in open loop:

Injectors

Injectors: This spreadsheet can also calculate injector scalar and latency using closed loop data. Latency can also be calculated using fast stationary revs. However, I have found that stationary data is not as reliable depending upon the intake type and how much it is affected by heat soak.

Using the 10-60 g/s range to calculate latency seems to be more accurate.

Keep in mind that when using this spreadsheet to scale the injectors and calculate latency that it assumes the MAF has already been scaled.